CSG Monitoring & Diagnostics

Posted on 25th July 2023 at 11:17

We are pleased to formally introduce our new service offering, CSG Monitoring & Diagnostics.

CSG’s offering has been designed to eradicate uncertainty and speculation regarding the cause of reported faults. Whether the fault is due to human error, component or system problems, electrical supply irregularities, or access control issues, CSG's solution records the changes in signals from the equipment control panel to a secure cloud.

CSG Monitoring & Diagnostics is especially useful in identifying intermittent faults. It often eliminates the need for on-site visits, improves the management and understanding of security personnel's role, and significantly reduces unnecessary maintenance and breakdown costs associated with service calls.

When a fault or issue is reported with a specific security gate system, accurate data can be extracted by CSG to aid in determining the cause thus removing inaccuracies of human memory from the process of system diagnosis. Above all, CSG Monitoring & Diagnostics protects the efficacy of the security system.

So how does it work?

CSG’s Monitoring & Diagnostics system is made up of two crucial components – hardware and software.

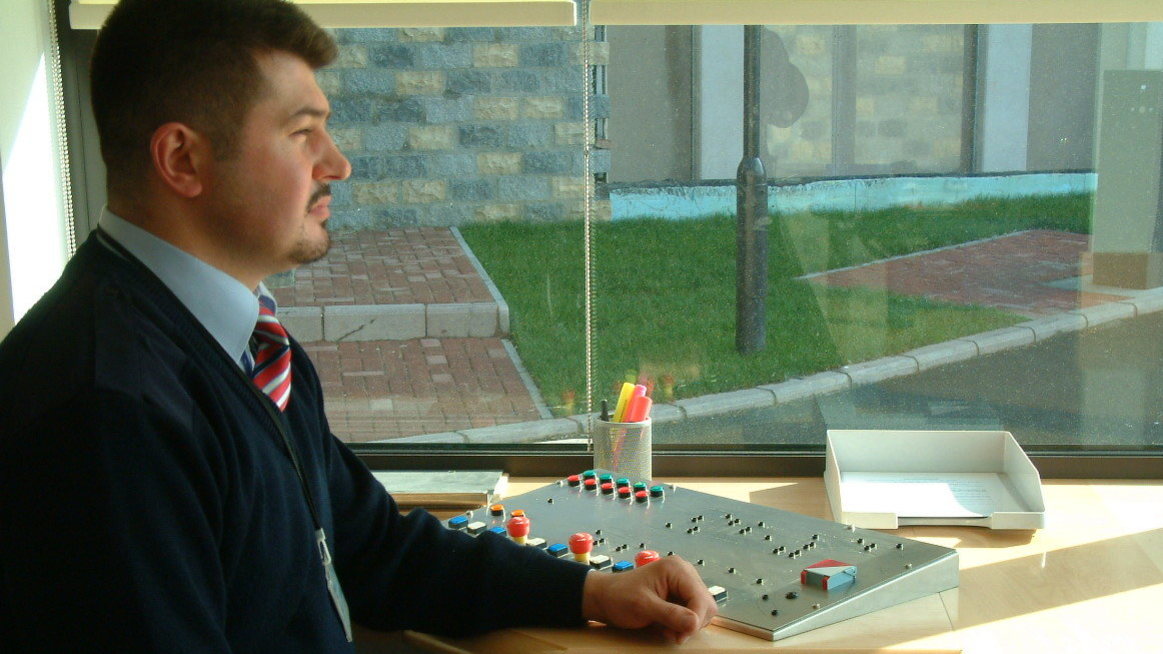

Hardware

Most CSG gate control systems are controlled by Programmable Logic Controllers (PLC) within dedicated control panels.

We recognise that not only is it a cyber security risk but it isn’t always feasible to hardwire an internet connection to all control panels. As a result, we partnered with a communications company to develop a GSM based microcontroller system to record the change of state of PLC signals.

Borrowing from the concept of traditional GSM relays, the CSG M&D unit is hard wired in parallel to the system PLC inputs and outputs and then PLC data is recorded to our online cloud via cellular technology (sim card with 3G connection).

Monitored PLC signals are determined on a system-by-system basis as the operational philosophy on each system can drastically vary. The common signals monitored are gate status open, gate status closed, and various safety devices. The mains supply is automatically detected from the CSG M&D unit.

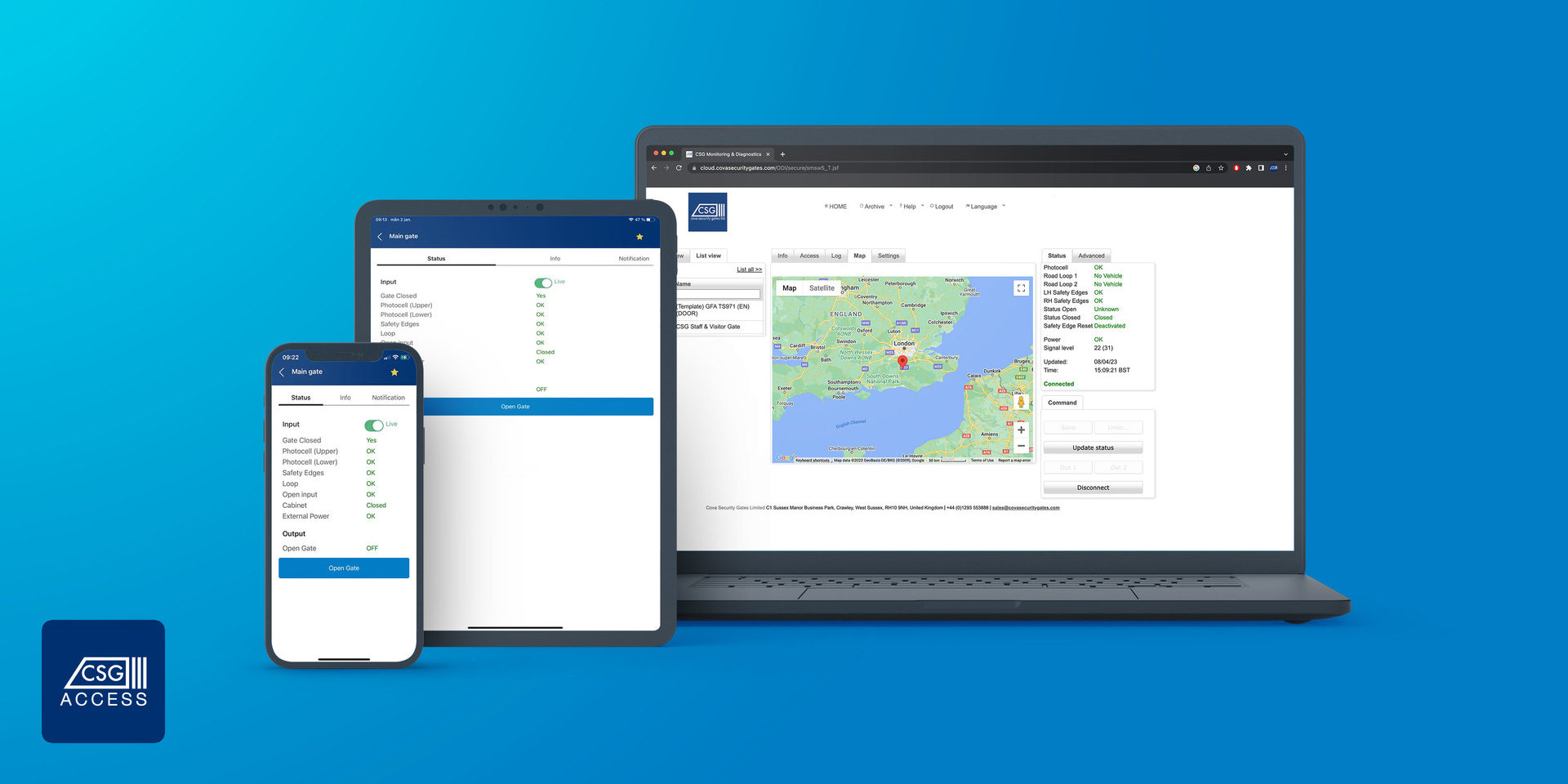

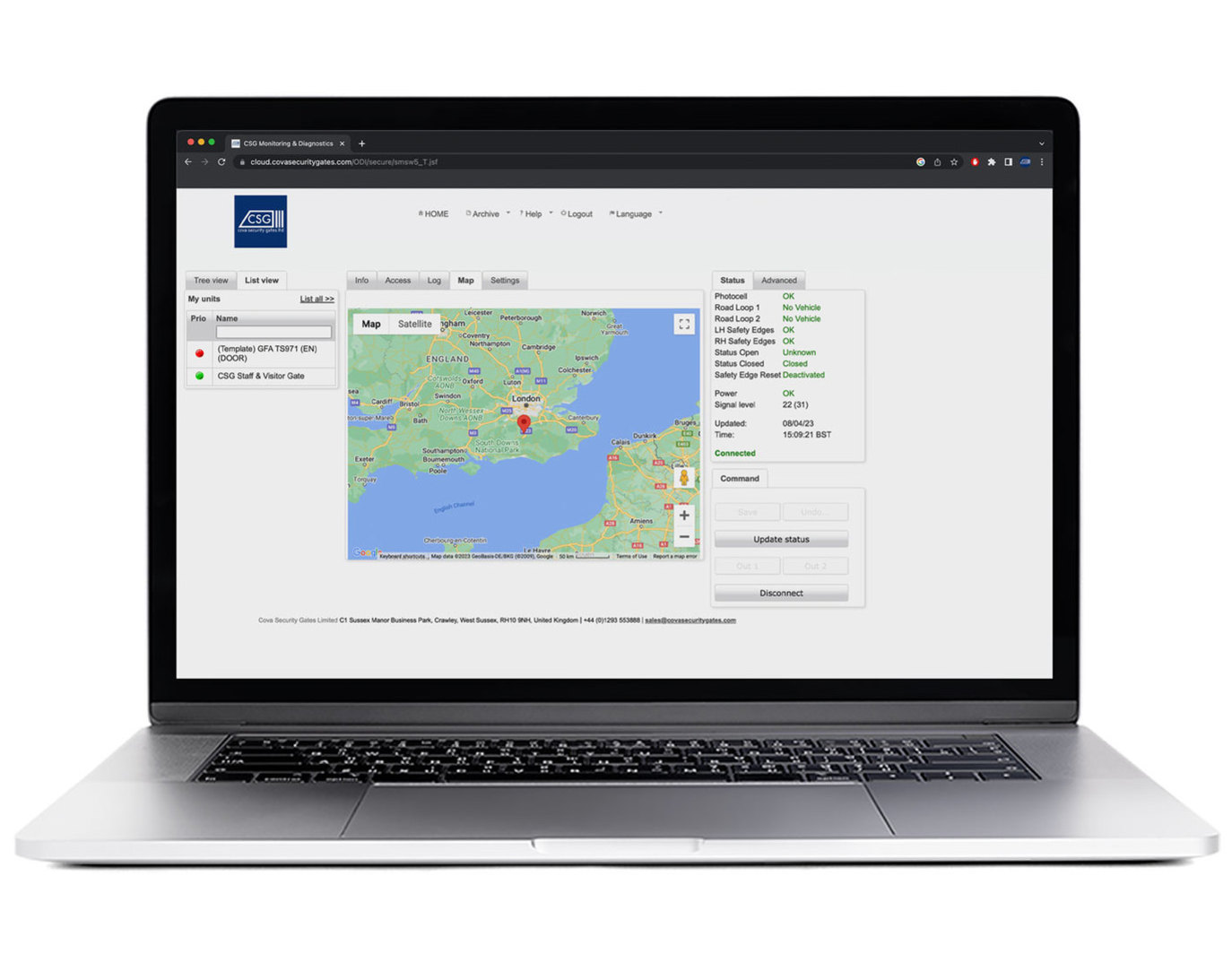

Software

Software is comprised of our web-based cloud that we use to configure, monitor, and extract data for analysis. Data is collected infinitely 24 hours a day, 365 days per a year. Within the cloud, during setup process, the following information is configured to make data extraction and navigation user friendly for CSG technical support team as well as other users of the cloud such as site staff (if required):

Gate Name

Site Name

Site Address – where it will show the site on a map within the cloud

Status signals labels (PLC signal data recorded)

In addition, to monitoring PLC signals, the cloud can send alerts and notifications. For example, when the gate is open, we can automate the system to send an email, text or smart phone notification to the relevant people. Our software is also equipped with an inbuilt gate operation counter that counts gate operation cycles to better calculate the frequency of required maintenances.

Is this offering only available on new product installations?

Nope! CSG Monitoring & Diagnostics is compatible with both old and new equipment. The M&D unit can be retrofitted to existing product control panels in the field.

What are the limitations?

CSG Monitoring & Diagnostics is available to all customers who own old and new equipment by CSG or other manufacturers. The solution is available on all automated perimeter security products, whether it be a bi-folding gate, road blocker or cantilevered sliding gate.

What about cyber security?

First and foremost, CSG Monitoring & Diagnostics' utilisation of GSM based technology is a much more safe and secure way of monitoring your gate system as opposed to the conventional method of connecting the PLC to the building management system.

CSG Monitoring & Diagnostics is structured with multiple tiers, spread across two different physical locations to ensure geographical diversity. These locations are securely linked through Layer3 using highly encrypted IPSEC-VPN. All forms of communication, including backup, replication, and administrative traffic, are consistently encrypted.

For more information, regarding the cyber security of CSG Monitoring & Diagnostics, please get in touch.

Are there any other features included within CSG Monitoring & Diagnostics?

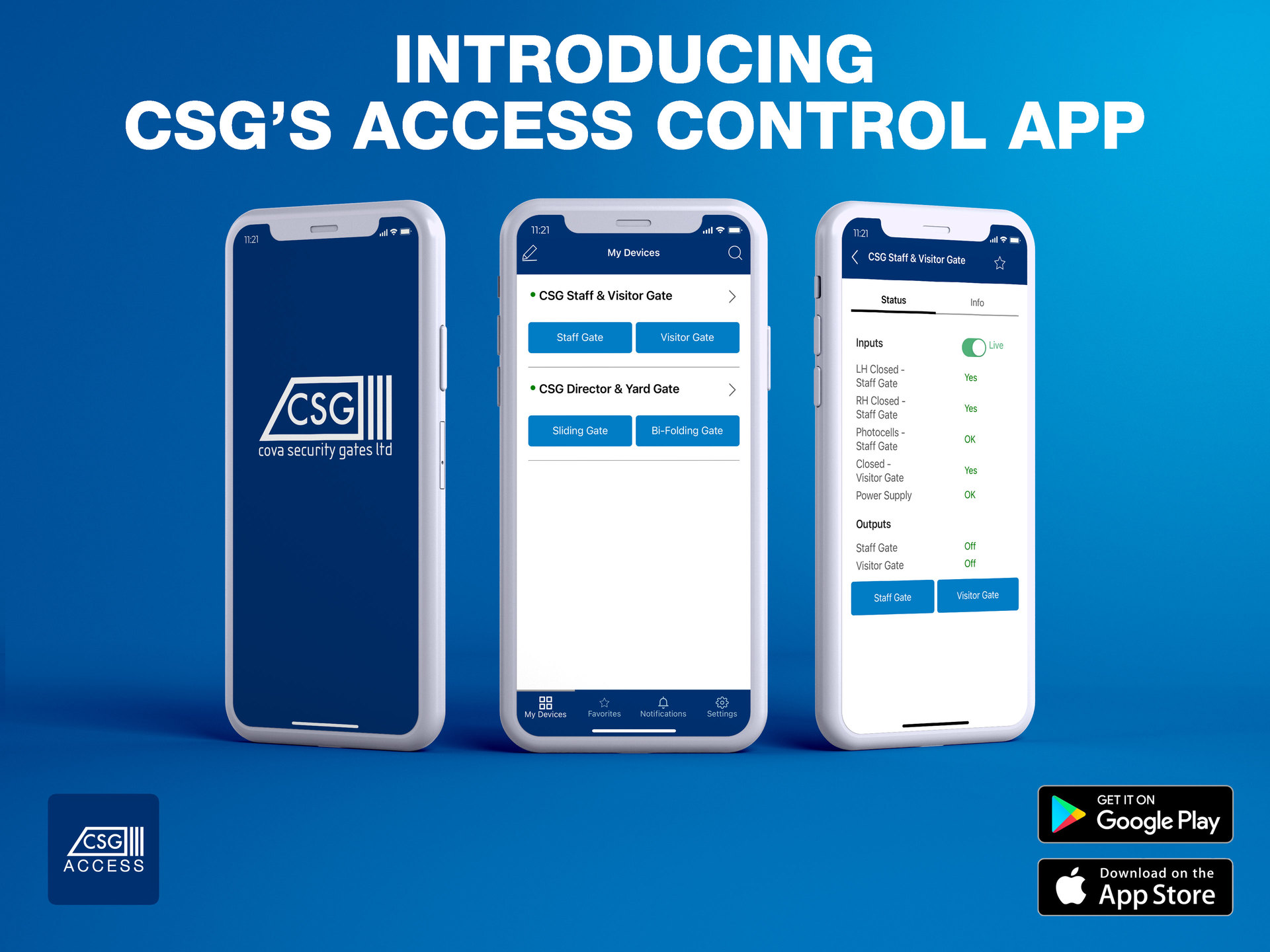

Yes! For clients with a lower security level requirement, if setup, configured, and physically connected, CSG Monitoring & Diagnostics can be used for access control via our CSG Access App. There is also compatibility to use the equipment as a GSM gate opener and 7-day time clock.

Success so far

We have seen the following statistics, since soft launching the CSG Monitoring & Diagnostics offering last year on selected sites:

50% of emergency call outs were resolved within a 30-minute remote technical support session, significantly reducing down time for the client by removing engineer travel time from the process.

Our engineers were able to travel to 40% of emergency call outs, with the correct components and materials to resolve the issue instantly. While our engineers carry common spare parts in their vans, correct replacement parts are not always guaranteed for every call out.

10% of the emergency call outs required attendance, to make the equipment safe and secure following a vehicle collision until replacement parts could be manufactured and installed at a later date.

Within the above samples:

30% of emergency call outs were due to lack of staff training and equipment mis-operation by security staff. These call outs were resolved without attending site. i.e., an emergency stop pressed (by accident) thus saving the client downtime and money.

15% of the gate systems were actively monitored for a 14 day period to diagnose ‘intermittent faults’ where the issue would typically disappear before the engineer got to site or reappear after they had left site. With the power of CSG M&D, we were able to cross reference our data that we collected with weather patterns and CCTV to ensure that we prescribed the correct resolution that ‘followed the science’.

Comments from our Executive Director and Chief Electrical Engineer:

“While we maintain a high standard for designing, manufacturing and installing quality perimeter security equipment, we are working with machinery. Like a car, wear and tear can be expected through time and usage.

CSG Monitoring & Diagnostics has unlocked a new capability for Cova to deliver a better service to its customers. It removes the inaccuracies of human memory from the fault finding process and enables us to carry out repairs and maintenance with a much more scientific approach.

Living in an era of self-driving cars, Amazon Alexa’s and other smart technology, why shouldn’t the same technology be used to monitor the perimeter security products we rely on to protect our people and places?"

Tagged as: Remote Monitoring and Diagnostics

Share this post: