Bi-Folding Gate Buying Guide

Posted on 29th September 2022 at 14:07

Introduction

If you are reading this article while researching perimeter security products (gates) that are currently on the market, or maybe you have an entrance / exit to your site that needs securing, we hope you find this bi-folding gate guide informative.

Cova Security Gated Ltd are experts in perimeter security and as such are specialists in bi-folding gates. In 2002, we introduced the first trackless bi-folding gate to market.

We have written this article in accordance with data collected from trusted sources and our 35 years’ experience in the design, manufacture and maintenance of bi-folding gates.

Faster than a swing gate...

One of the benefits of bi-folding gates is that they open and close in half the time compared to a traditional swing gate. It is also true that bi-folding gates require very little room for the gate to swing open as the gate leaves are half the length of a swing gate equivalent. Therefore bi-folding gates often over-come entrance limitations in freeing up valuable road, driveway and or car park space.

Sometimes called a speed gate and more

Also commonly referred to as Folding Gates, Radius Gates, Scissor Gates, Sliding Collapsible Gates, Concertina Gates and Bi Parting Gates.

The name ‘speed gate’ was a term coined by the industry during the products original conception as it is faster in operation than a conventional swing gate. Now, we call it a bi-folding gate to avoid confusion because, pedestrian lane control gates found in buildings such as airport are also called speed gates.

A bi-folding gate is an assembly of two folding leaves attached to a post, folding together as they swing open. On closing operation, movement is reversed, so the gate leaves fold out. The leading leaf and trailing leaf leaves are connected by hinges.

Tracked vs Trackless

There are two types of bi-folding gates available, tracked and trackless. The track or trackless ‘mechanism’ enables the trailing and leading leaves to fold in (open operation) or fold out (close operation). When determining your bi-folding gate, it is important to establish whether you require tracked or trackless as both have their advantages and disadvantages.

Tracked bi-folding gates are often lower in initial cost than trackless alternatives as folding mechanisms are not required. Instead tracked bi-folding gates comprise of an over-head mounted track or a ground track, a channel section across the finish floor level (FFL) of the road surface that acts as a guide:

Overhead Tracked Bi-Folding Gate

Advantages

The gate posts can be positioned inside a structural opening (within a building) thus maximising entrance width.

The operating box located at the top of the gate posts, can be cleated to the building structure.

Gate can be supplied to any width or height.

Substantial product life due to heavy duty construction.

Disadvantages

Cost of product can be significantly higher to alternative solutions.

Access plant / equipment is required for maintenance.

Longer installation time in comparison to trackless bi-folding gates.

Ground Tracked Bi-Folding Gate

Advantages

Lower product cost.

Disadvantages

Higher civil work costs as track must be installed on to a foundation base, spanning the road width.

Road degradation combined with vehicles driving across the open track, inevitably leads to track distortion. Tracking of gate over time becomes unreliable.

Regular maintenance is required as leaves, gravel, stones and litter will clog track thus preventing reliable operation.

Track has to be installed level therefore, roadway must be suitable. Track cannot be installed into a road with any camber.

Short product life expectancy.

Bi-Folding Gate Mechanisms

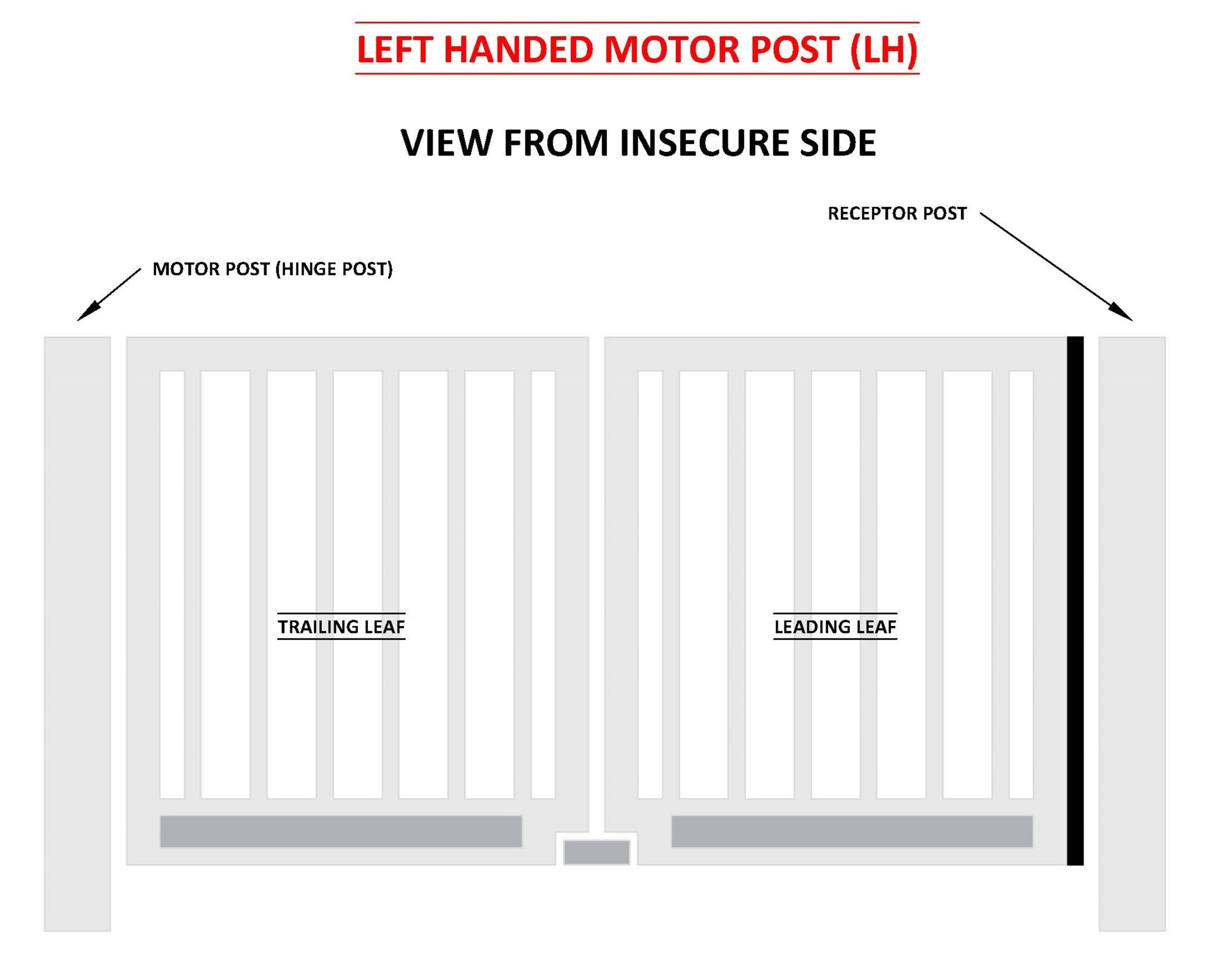

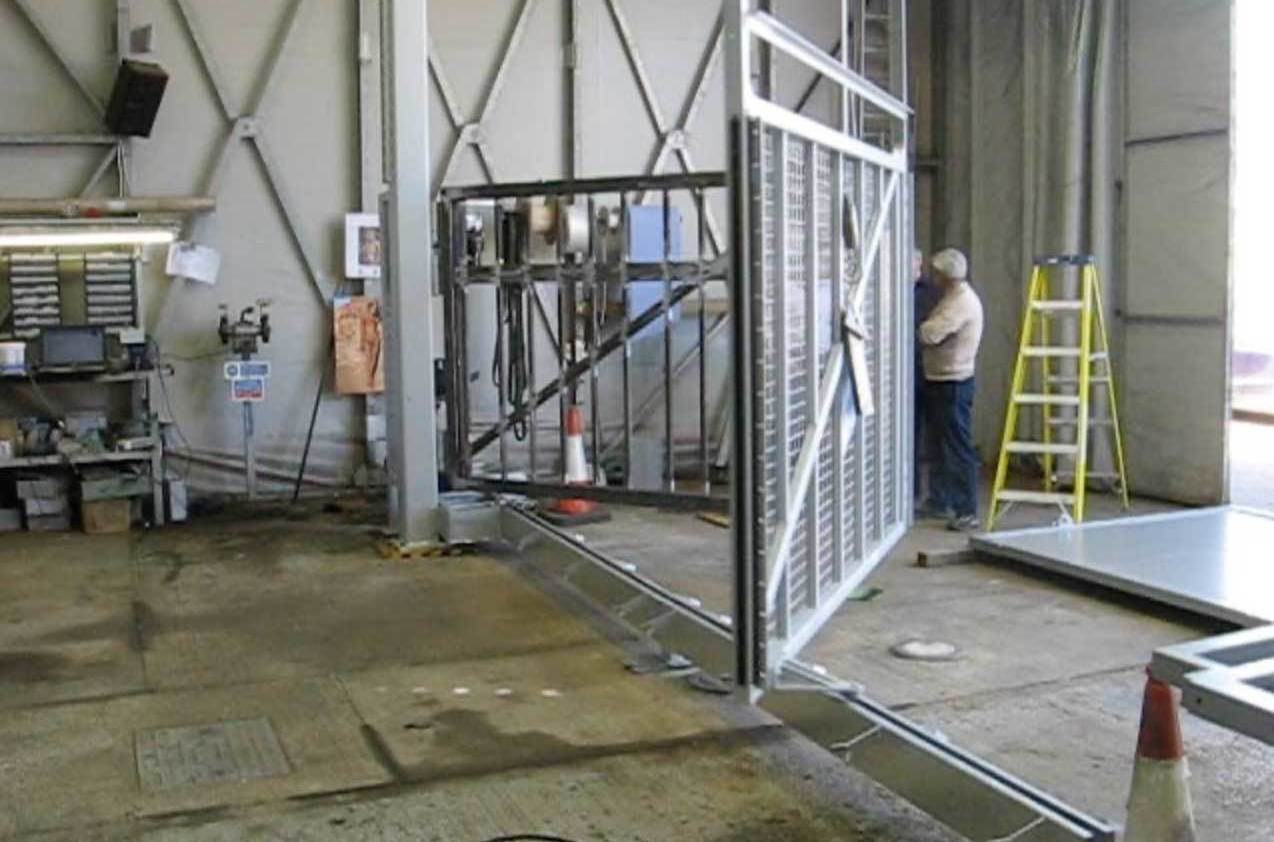

In 2002, Cova Security Gates Ltd introduced the first trackless bi-folding gate to market. A chain and sprocket mechanism was utilised, mounted on the top of the gate between the motor post and hinges joining the trailing and leading leaves (image 1). Shortly after, we introduced the rack and pinion mechanism (mounted on the bottom) as an alternative for customers who wanted spikes on their gates (image 2).

Since then, other manufacturers have introduced adapted and alternative mechanisms but the idea remains. The rack and pinion mechanism can now be purchased as an off-the-shelf item to be retrofitted for domestic installers.

Chain & Sprocket Mechanism

Chain & sprocket located on the top section of the gate.

Advantages

Low maintenance.

Easy to install, setup and adjust.

As the drive gear is located at the top of the gate, less safety devices are required.

Disadvantages

Could be less aesthetically pleasing.

Installation of gate leaf topping such as spikes and barb wire - more difficult to achieve.

Rack & Pinion Mechanism

Rack & pinion located on the bottom section of the gate.

Advantages

Drive mechanism is located on the bottom of the gate, allowing any form of gate topping to be provided i.e., spikes, barb wire, electric fence detection etc.

Rack and pinion bi-folding gates are popular for their aesthetic potential.

Disadvantages

As rack and pinion drive is at low level, more consideration needs to be given to protecting users.

Trackless bi-folding gates are easier and quicker to install compared to their tracked alternatives. Top tracked bi-folding gates are inherintly reliable in operation and will give many years service as oppossed to bi-folding gates utilising a ground track which inevitably detoriate at a greater rate. In summary, any bi-folding gate type that doesn't use a ground track will be far superior in operational reliability. This is equally true in terms of maintenance.

Configurations

You can purchase bi-folding gates in two variations, either a single unit or a bi-parting pair. A single unit (Image 3) means that there is 1no. motor post, 1no. trailing leaf, 1no. leading leaf and 1no. receptor post. A bi-parting pair (Image 4) is when there is 2no. motor posts, 2no. trailing leaves and 2no. leading leaves.

Single Unit

Bi-Parting Pair

So how do you select?

The choice of bi-folding gate may be based on specification, budget, engineering or mixture of these factors. The maximum width (road opening) of a single unit bi-folding gate is almost always half that of a bi-parting pair (as a bi-parting pair is essentially 2no. single units without the receptor post). For smaller entrances where a single unit could fit, some clients prefer to utilise a bi-parting pair. The reason for this can be lack of room for the gate to swing open or just because the gate will open and close faster. A bi-parting pair at the same width of a single unit will open faster as there are 4no. gate leaves and 2no. motors. A bi-parting pair may be more expensive though as you are effectively purchasing 2no. gates which means double the components and materials for the manufacturer.

Left Hand and Right Hand

This is often a very confusing subject and many people have their own understanding however the common approach is left and right hand is always determined by looking at the gate from the insecure side or attack side (outside of the perimeter).

Hydraulic vs Electromechanical

Some manufacturers utilise hydraulic, electromechanical and occasionally pneumatic systems to operate their bi-folding gates. During our early years in business, we invested in research of pneumatic systems however we found the solution inferior compared to hydraulic. At Cova Security Gates, we provide both hydraulic and electromechanical solutions that are designed and manufactured specifically for our product range. Several factors will determine which solution is best:

Electromechanical (Electric Motor)

Why This Solution?

Easier to source component in comparison to hydraulics.

Easier to install and maintain.

Better performance in colder climates (i.e., Scandinavia) than hydraulics.

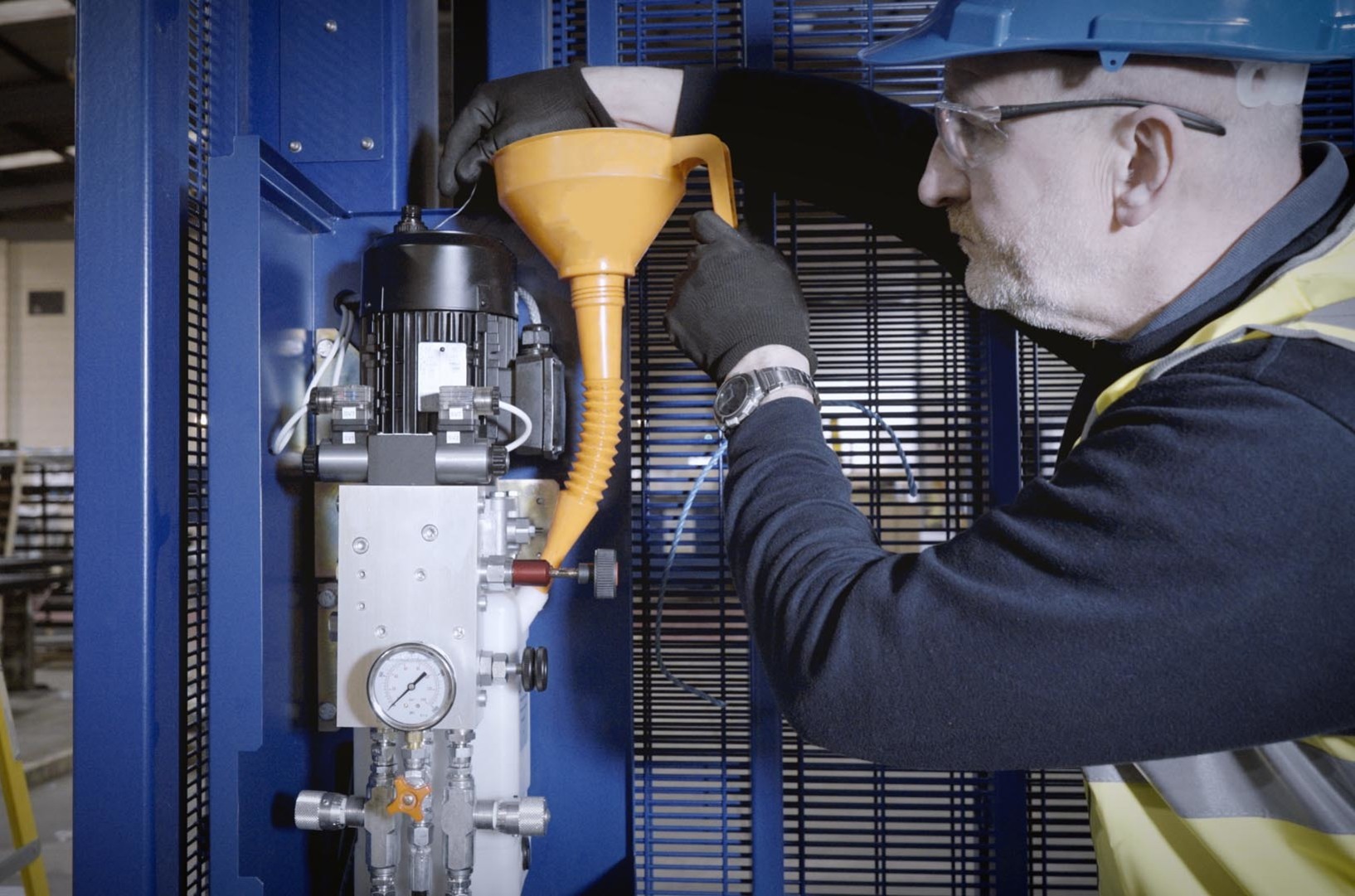

Hydraulic System

Why This Solution?

Large bi-folding gate heights and road way widths can be achieved. while reliably operating against windspeed.

Heavy (weight) bi-folding gates due infil cladding and topping operate reliably when a hydraulic drive is utilised.

Hydraulic bi-folding gates operate reliably against fast wind speeds. A common issue: In high wind speeds, the gate leaf is arrested, preventing a full opening or closing operation as the gate leaf acts as a sail.

Many manufacturers utilise DIY gate kits consisting of control boards, hydraulic actuators or motors to operate their gates. These kits are designed to meet domestic market requirements at a low cost, offering a plug-and-play solution for installers to automate gates to desired control philosophies via dipswitches or joysticks. The kits are programmed like a ‘Casio Watch’ making them popular among installers serving the domestic market.

Here at Cova Security Gates , we design and manufacture everything from the physical gates and control systems using the highest quality components available. From time to time, we do utilise DIY kits for bespoke ‘one-off’ products when appropriate.

Operational Philosophy

When purchasing your bi-folding gate, it is crucial that you know how you want your gate to operate, i.e., will it be open all day between the hours of 9am to 5pm or will it remain closed until an open command (a prompt to open the gate) is given? This is determined through an operational philosophy written and approved between the gate supplier and customer.

Here at Cova Security Gates, the operational philosophy document is used as a reference for teams during the design, manufacture, and commissioning process of a gate system, as such this is a critical step in ensuring get the best solution.

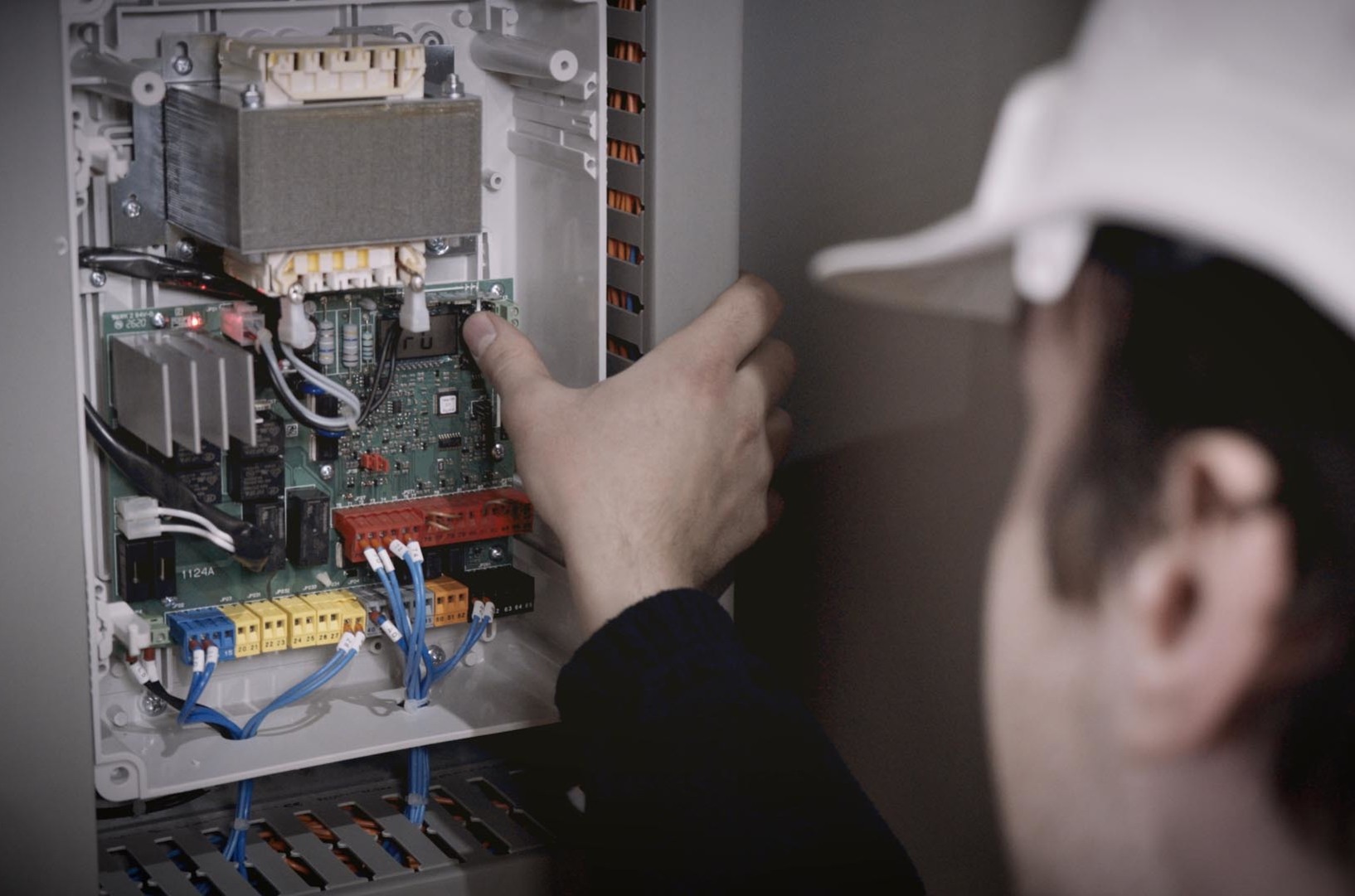

PLC Based Control Panel vs Off-the-shelf Control Board

A programmable logic controller (PLC) is a compact digital microprocessor used for building management and industrial machine automation applications. PLCs, receive input signals from buttons, switches, and sensors. Signals are processed to programmed logic and then outputted to devices such as motors, lamps, and visual indicators. This process constantly repeats during operation. In addition to PLCs, various other components are utilised such as: variable frequency drive inverters (VFD), terminals, contactors, circuit breakers, resistors, capacitors, power supplies, relays, safety edge controllers and road loop amplifiers.

An off the shelf control board is a printed circuit board (PCB) that come as part of a DIY gate kit as described above.

PLC Based Control Panel

Advantages

Any operational philosophy can be achieved.

More flexibility to deliver last minute U-turns on operational philosophy requirements as the PLC is completely customisable through additional expansion units and programming.

Replacement components can be sourced anywhere in the world as PLCs are designed and manufactured by large electrical component suppliers such as Schneider Electric.

Disadvantages

Requires knowledge and skills, so this option will only be provided by professional skilled organisations with electrical engineering credentials.

Off-the-shelf Control Board

Advantages

Low cost.

Available as a kit with a motor or actuator.

Very little or no knowledge required in engineering.

Disadvantages

If the control board requires replacing and the manufacturer has discontinued the product, the end user will have to purchase a brand new control board and actuator / motor kit.

Confined to control board features. More advanced operational philosophies require expansion boards – if available.

The end-client who is dealing with the company supplying an automated gate (utilising an off the shelf control board) may not have assurance that their gate is precision engineered.

PLC-based control systems are the recognised way of controlling machines within the automation community – i.e., lifts, conveyor belts, pumps, robotics, building management and traffic management. The Health and Safety Executive (HSE) in the UK recognise, security gates as machines. We would always recommend the use of a PLC because it enables flexibility to achieve bespoke operational philosophies while offering assurance against redundancy in the future. For example, most control boards do not offer traffic light compatibility by default, and they tend to be upgraded or discontinued frequently. On the other hand, PLCs can be programmed anyway you wish and replacement parts can be sourced anywhere in the world.

Tagged as: Head Office News

Share this post: